Solutions to earth-leakage faults in production plants with an HRG system

Earth-leakage faults are no small matter and the cause of approximately 90 percent of the electrical faults in a system. This often has expensive consequences, such as long plant downtimes and high maintenance costs, a risk that no company wants to run. It is therefore important to plan for suitable solutions to the problem of earth-leakage faults already when designing a production plant.

In the following we detail what we take into account when planning future-oriented solutions to earth-leakage faults for high-tech manufacturing facilities and how we develop solutions that are geared to individual requirements.

Which supply system is best suited?

The first thing to decide is which supply system shall be used for a new production plant: an unearthed, a solidly earthed, a low resistance grounded (LRG) or a high resistance grounded (HRG) system? For applications that must not shut down even in the event of a fault, IT systems (unearthed systems) are the ideal solution. However, in mining and in the American and Australian region for instance also HRG systems are very common (Read more about high restistance grounding).

Which energy sources shall be integrated?

When building new production plants, many companies rely totally or partially on renewable energy sources. These may be photovoltaic systems, wind power plants, or biogas installations. These systems then need to be integrated into the chosen supply system. The problem: Depending on the model or manufacturer of the system, individual adaptations may become necessary to make them compatible to the supply system.

Which Bender solutions fits?

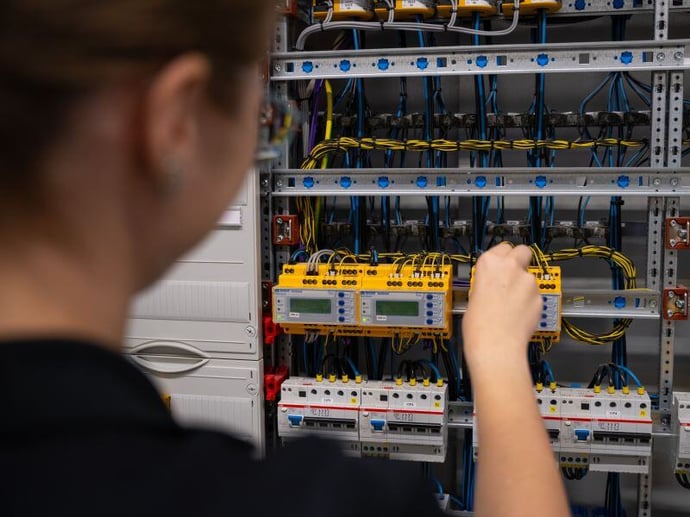

High-tech facilities often mean complex requirements regarding electrical safety. For instance they often use speed-controlled medium-voltage drives with earthed and unearthed sections. No problem for the experts from Bender: In the course of many years our array of products has been developed further and further and contains residual current monitoring devices for practically every conceivable application. After extensive consultations and planning with our customers, we select efficient, long-lived, and, most of all, safe solutions for you.

Would you like to know what this can look like?

We are happy to oblige! Let's look at the manufacturing of heavy machinery: When building their new site in Longview/Texas, Komatsu Ltd., a manufacturer of construction machinery, relied on the best available electrical safety from the very beginning and brought our subsidiary Bender Inc. on board. The aim: no earth-leakage faults in the HRG system and an end to expensive plant shutdowns. The solution our specialists found for Komatsu is called RCMS490. This residual current monitor with twelve measuring channels is ideal when it comes to ensuring high availability of an HRG system with speed-controlled drives as the one Komatsu uses.

For HRG systems the RCMS490 provides a solution to earth-leakage faults which offers 4 central advantages

- Flexibility: Optionally AC, pulsed DC, or AC/DC sensitive measuring as the measuring-current transformers can be selected for every channel

- Sensitivity: Fault detection independent of the fundamental frequency of the fault current

- Safety: Wide frequency response range for excellent protection with nonlinear loads

- Prevention: Enhanced predictive maintenance owing to very accurate measuring and, due to this, detection of trends regarding the earth leakage current

Bottomline after one year: success

In the meantime Komatsu has been producing components for open-pit-mining machinery at its new Texas site for more than a year. And the Bender solution for earth-leakage faults, the RCMS490, is doing its job reliably and with enormous success. In its first year of operation alone, the system recognised six earth-leakage faults and hence prevented extensive damage to property and people (Read the full story in the MONITOR Magazine).

What are you planning?

Is your company about to plan a new production facility or a new production site, too? For the highest level of electrical safety, this will entail a carefully designed, individually planned solution to earth-leakage faults for your HRG system. Such an investment will prevent production downtimes due to earth-leakage faults and will save high maintenance and downtime costs. In light of this, it will be worthwhile in any case!

Do you have any questions regarding the project, the solution or product, feel free to contact us.

.jpg?width=530&height=298&name=Brandschutz_Feuer_530x298px_AdobeStock_86117213%20(2).jpg)