Reduce the cost of periodic inspections

In many companies and buildings, whether industrial plants, office buildings, schools, factory buildings, hospitals or even swimming pools, the responsible electricians are constantly faced with the question of how to carry out the periodic inspections. The organisational, time and personnel costs are very high in any case. This is why the periodic inspection is often not carried out at all.

In this article, we will show you how you can significantly reduce the time and effort required for periodic verification by using intelligent measurement technology.

The dilemma: High costs and production losses

Every responsible electrician knows the problem: Electrical systems and equipment must be checked for safety at least every four years.

Some of the tasks associated with the periodic inspection (such as the visual inspection) can be completed relatively easily and quickly. However, when it comes to measuring the insulation resistance Riso, several problems arise.

- In order to measure the insulation resistance of an electrical system or equipment, the system must be switched off or the equipment taken out of service.

- In addition, systems, system components, machines and other equipment must in most cases be disconnected from the rest of the electrical installation in order to measure the insulation resistance.

- Because entire systems, system components, buildings or floors have to be switched off and disconnected to measure the insulation resistance, the systems are not available during this time. This results in production downtimes or it is not possible to work in these buildings or systems.

- As some systems or buildings have to be disconnected from the power grid, the periodic inspection must be well planned and organised to minimise downtime and the associated loss of production.

- During the periodic inspection, the technical personnel are not available for other tasks.

- The shortage of skilled labour also affects electricians. There is not enough staff available for a complex periodic inspection.

- Errors can occur when reconnecting electrical equipment (e.g. N conductor not connected correctly and thus loss of the neutral point). This delays the restart of machines and systems.

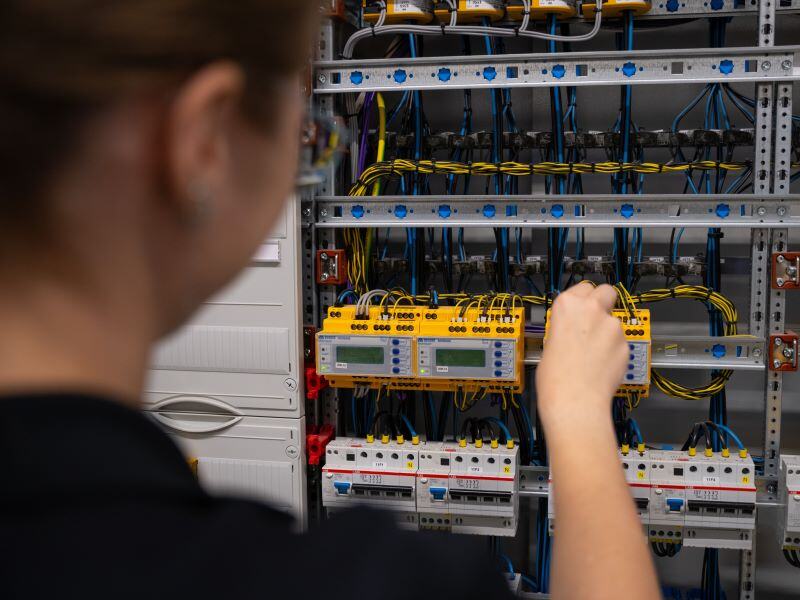

Technician at the control cabinet

The solution: Continuous residual current monitoring instead of selective RISO measurement

In order to avoid the shutdown of electrical systems and the associated production losses and at the same time significantly reduce the high cost of the periodic inspection, permanent monitoring of the electrical systems using suitable measurement technology is necessary. In earthed power supply systems (TN or TT system), residual current monitors are used for this purpose.

Residual current monitoring devices continuously measure the currents flowing in and out of circuits. Ideally, the residual currents are at 0. If, on the other hand, the incoming and outgoing currents are very different, this is an indication of residual currents or a defective component in the electrical system. (How does residual current monitoring work?)

Residual current monitoring systems are therefore the method of choice in earthed power grids for detecting faults in electrical systems. For this reason, according to the periodic inspection, the costly Riso measurement can also be dispensed with if the systems are continuously maintained by qualified electricians and checked by permanent or continuous metrological measures during operation. The residual current measurement technology from Bender fully fulfils the requirements for periodic inspections.

Residual current monitoring devices in a control cabinet

The result: Significantly reduced effort for periodic inspection

Residual current monitoring can significantly reduce the time and effort required for periodic inspections.

- The organisational effort is eliminated. No interdisciplinary agreements due to the need to switch off electrical systems.

- This reduces the time required. The time-consuming measurement of the insulation resistance RISO of machines, systems and other equipment is no longer necessary.

- Personnel costs are reduced. Fewer staff are needed for the tests.

The use of residual current monitoring offers further decisive advantages:

- There is no need to disconnect and connect electrical components for RISO measurement. This prevents errors during recommissioning after the test.

- In contrast to the classic test every four years, which is only a snapshot, the electrical systems and equipment are constantly monitored using residual current technology. Faults in the system can therefore be identified and rectified immediately.

Residual current monitoring devices in a control cabinet

Your benefit: The simplified periodic inspection works (almost) everywhere

Permanent residual current monitoring works in almost all electrical systems, whether large or small. Bender offers a wide range of residual current monitoring devices that are suitable for many different requirements. This allows you to significantly reduce the time and effort required for the periodic inspection in your company or building.

Our offer: Let our electrical safety experts advise you

Every electrical system is different, which is why residual current monitoring is not available off the shelf. We offer you personalised advice. Whether you want to plan or modernise your system, our experts will be happy to answer your specific questions and requirements and advise you.

Further information

Would you like more information on residual current monitoring devices or on our solutions for a simplified periodic inspection?

Download our brochure Product Overview - Residual Current Monitoring