Operating solar parks safely and efficiently in the long-term

Signs of ageing in solar parks and large-scale PV systems can quickly lead to problems with electrical safety. Insulation fault location solutions can help identify and correct problems caused by degradation. This means that even older ground-mounted systems can be operated safely in the long-term.

In this article you will learn what needs to be considered with regard to the electrical safety of ageing large-scale PV systems and how Bender is proceeding to maintain safety, minimise failure risks, ensure electrical safety and protect people

Causes and consequences of the ageing of large-scale PV systems

Display scratched, moisture penetrated, battery life reduced: Signs of ageing and wear and tear, which everyone knows from smartphones, do not stop at large-scale PV systems. Day after day, they are exposed to sun, wind and weather, as well as sometimes considerable temperature fluctuations, without protection. These influences accelerate the natural ageing of the materials of a PV system. In the process, they also reduce their performance and the electrical safety of large-scale PV systems - with sometimes dangerous consequences for operators and technicians.

Know what applies: Standards for ground-mounted PV systems

The normative requirements for PV systems (standard IEC 60364-7-712:2017) define the requirements for electrical safety. Usually, solar parks are operated as an unearthed IT system. Suitable insulation monitoring devices (IMD) according to DIN EN 61557-8) are required for this purpose. IMDs (Insulation Monitoring Devices), also called ISO monitors in the PV industry, which meet the requirements for PV, must not only tolerate DC voltage fluctuations of the PV generator, but also adapt to changes in the physically induced leakage capacitance and provide correct measurement results. Faulty alarms or even switching off the PV generator due to incorrect measurement results are not permitted.

How weather affects the electrical safety of PV parks

A significant factor that has an impact on the economic efficiency and electrical safety of a large-scale PV system is the weather. The interaction of temperature and humidity leads to a change in the insulation value of the PV systems. Especially in damp and cold weather, the physical measured values reach critical states. Many insulation measuring devices are no longer able to detect these changes correctly and consequently provide incorrect measurement results. These in turn can become a hazard for operators and people working on the system and must therefore be prevented at all costs. Furthermore, they can cause damage to the PV ground-mounted systems themselves and thus reduce their economic viability.

Decreasing electrical safety in ageing PV systems

When purchasing large-scale PV systems, only a few operators think about their possible ageing and the resulting dangers. If the performance noticeably declines after ten or more years and earnings drop as a result, they usually quickly learn the associated technical term for this: Degradation describes not only the environmental and mechanical wear of the large-scale PV system, but also a performance-reducing polarisation effect of the semiconductor structures as Potential Induced Degradation (PID). This can be reversed by a special procedure called PID shifting, PID recovery or anti-PID, but the higher-level IMD must be deactivated for this. After a PID shift has been performed, the IMD is reactivated and starts the measurement cycle. In order for the measured values to be correct again, the IMD must first recognise the new system status (e.g. changed leakage capacitance), which many conventional systems cannot do reliably.

How does Bender make large-scale PV systems electrically safe and economical?

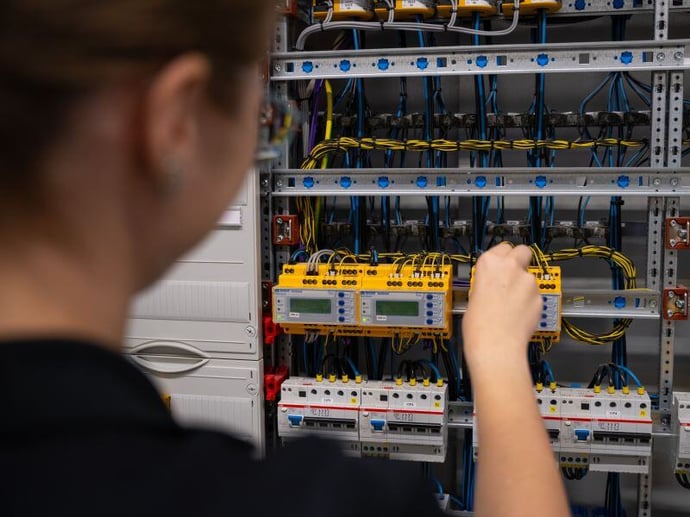

In order to meet the complex requirements of standards, weather influences and the ageing process, Bender has developed special insulation monitoring devices for large-scale PV systems. These work with an adaptive measurement method and help to ensure the safety and efficiency of solar parks in the long term.

Intelligent insulation monitoring devices identify fluctuations in the insulation

resistance (Rf) and leakage capacitance (Ce) caused by environmental

influences throughout the day and factor them into the evaluation.

Ageing PV installations with considerably deteriorating electrical

properties will lead to increasingly large problems in the years to come.

Planners of large-scale pv-systems are facing the challinge to operate them electrically safe.

Four core benefits of Bender insulation monitoring for large-scale PV systems:

1. Standard-compliant design

2. Automatic adaptation to environmental influences

3. Reliable detection of insulation resistance and leakage capacitance

4. Interference-free measurement after PID shifting

Do you want to operate your large-scale PV system safely and efficiently in the long term?

scale PV system that is already showing the first signs of degradation? Are you planning PID shifting for your plant? In all cases, it is worth considering insulation monitoring technology. You can find important tips on this in our practical guide "Electrical safety in large-scale PV systems“ here.

If you would like to find out more or already have specific questions about this, it is best to speak directly to our experts about the application possibilities and advantages of Bender insulation monitoring systems with adaptive measuring principle. Simply contact us