Electrical safety on the world's largest hospital ship

The safety of electrical equipment and networks is even more important on the high seas than on land. Especially when operating on a hospital ship, it can be vital to detect insulation faults quickly, locate them safely and rectify them competently. With a medical IT system and measures for insulation monitoring and insulation fault location, Bender has optimised electrical safety on the largest hospital ship in the world, the Global Mercy from the Mercy Ships Organisation.

Find out in this article about the importance of electrical safety at sea and what Bender has done on board a hospital ship to ensure that the technicians on board always have an electrical overview.

3 problem areas for Insulation fault location at sea

No matter whether it's a cruise ship, an offshore wind turbine or a submarine: Faults in the electrical system are always more complex on the high seas than on land and often present crew and technicians with organisational, economic and technical challenges.

1. Organisational problems with troubleshooting

The search for insulation faults at sea is an organisational challenge that must be well planned. In the best case, sufficient redundancies are available so that individual distribution circuits can be examined separately. If this is not the case, on a cruise ship, for example, it can lead to individual distribution boards be switched off for a short time, making comfort functions or installations unavailable. In order not to disturb passengers, corresponding measures are often taken at night. However, this is not possible on a hospital ship with its operating theatres and medical rooms. Therefore, more flexibility and effort is required here when planning the medical IT system.

2. Troubleshooting at sea results in high costs

But even if the organisational framework of troubleshooting at sea is right, it is costly in many cases. In the case of offshore wind power plants, for example, the arrival of the technicians is time-consuming and cost-intensive. On site, there are then often only weather-limited time windows available for the work. This is even more true for large transport ships when they cannot proceed because of electrical problems. In view of the high daily rates of several hundred thousand euros, the financial scale of a loss quickly becomes large and the pressure to find a fault correspondingly high.

3. Technical problems with insulation fault location

Another problem with electrical faults at sea occurs when the damage cannot be repaired by one's own crew. Then external specialists usually have to be flown in at high cost. This is another reason why investments in electrical safety installations usually pay off very quickly. All the more so, of course, when it comes to a submarine, for example, where no external specialists can be brought on board in the event of a problem and any failure means danger to life or reconnaissance. A safe and reliably functioning troubleshooting system can help the technicians on board to find and rectify faults quickly.

Troubleshooting on board is this easy – using the example of Global Mercy

The aid organisation Mercy Ships uses its hospital ships to care for people who have no access to medical care. The new ship, the Global Mercy, is 174 metres long and weighs 37,000 tonnes. It was specially designed as a civilian floating hospital and has six operating theatres and an intensive care unit with seven beds. Around 200 patients can be cared for on board at the same time. To ensure that this can be done well and safely at all times, the ship needs a reliable electrical supply mains. The medical facilities also need a robust and self-sufficient IT system that does not shut down in the event of a fault. Bender was entrusted with this task and was able to install a powerful and electrically safe solution here.

This fulfils the following requirements, among others:

- Three coupled IT networks for on-board power supply for maximum flexibility and redundancy

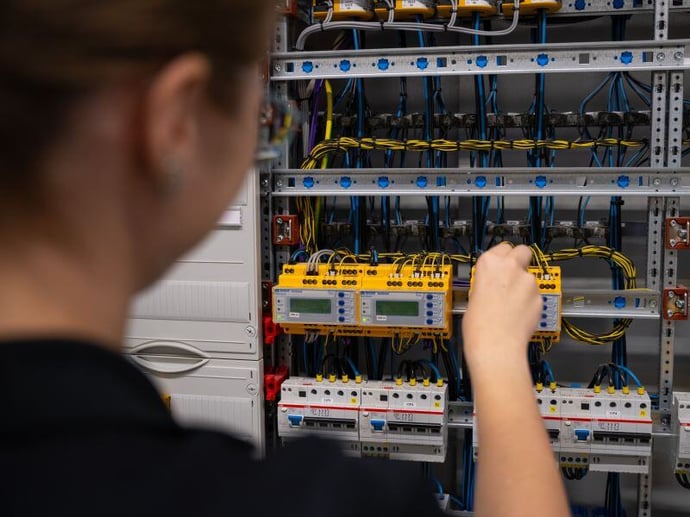

- Equipped with current transformers, ISOMETER® and ISOSCAN® systems for reliable detection and fast localisation of insulation faults

- Monitoring of all consumers of the emergency control panel, because these must also be available in case of emergency

- Individual monitoring of critical consumers in order to be able to quickly allocate or exclude sources of error

ISOMETER® iso685, insulation fault locators ISOSCAN® EDS440 and measuring current transformers LINETRAXX® of the CTAC series, among others, were used to implement the solution (You can read the detailed story in the Monitor report).

Do you need electrical safety at sea?

Would you like to increase the electrical safety on a cargo or passenger ship? Are you looking for ways to speed up electrical troubleshooting for offshore wind farms or are you looking for an electrically safe solution for your submarine or other watercraft?

Our experts offer comprehensive know-how and solutions for safe power supply for all maritime applications on the high seas and in coastal areas - from ships and submarines in the civil and military sector to crane and container systems. We will be happy to advise you on the possibilities that Bender and the IT system offer you. Contact our expert Benjamin Greiff.